In the process of automotive electrification and intelligent transformation, connectors serve as the core hub of electrical systems, directly influencing vehicle performance and safety. With nearly 20 years of experience in the precision connector industry, Denentech's 3.5mm pitch dual-row automotive connectors have become the preferred supporting components for core systems of new energy vehicles, thanks to their high-density and high-reliability advantages, providing efficient connectivity solutions for global automakers.

The

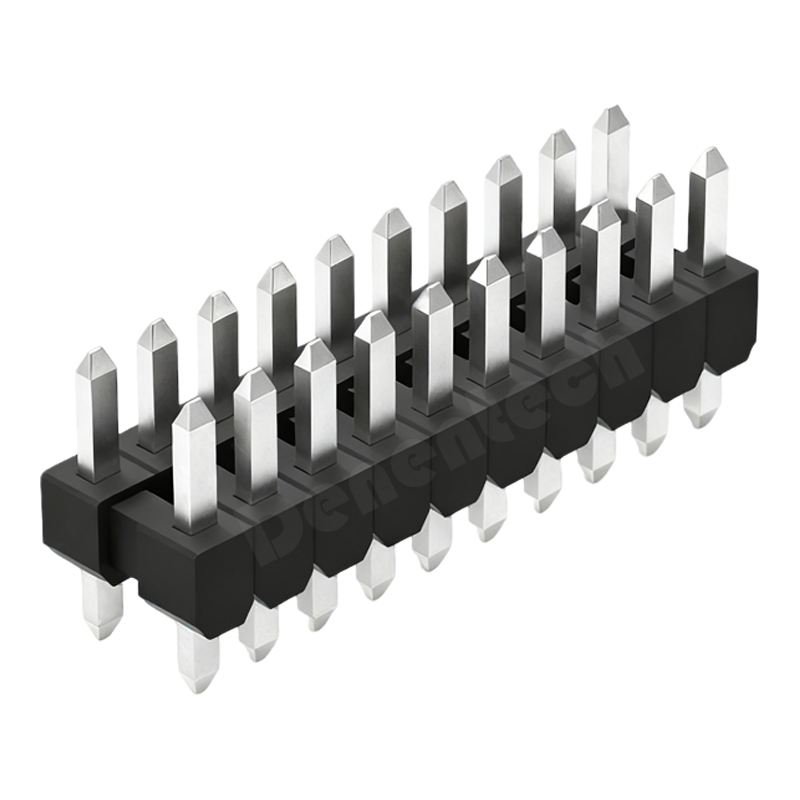

3.5mm pitch dual-row automotive connector is a vehicle-mounted connectivity device with a pin center spacing of 3.5mm and a dual-row arrangement. Designed specifically for high-voltage transmission and signal interaction under complex operating conditions, it boasts prominent core advantages:

- High-Density Integration: The dual-row structure improves space utilization, covering mainstream specifications of 10-12 pins, and adapts to the compact requirements of automotive zone electronic architectures.

- High-Voltage Safety Guarantee: With a rated voltage of up to 1000V, it meets the insulation requirements of 800V high-voltage platforms and is suitable for high-voltage scenarios such as three-electric systems.

- Convenient and Stable Design: Modular design enables compatibility with dual single-row sockets, and the X/Y keying anti-misinsertion + side-lock structure ensures accurate mating and firm connection.

Validated by long-term market practice, this series of products from Denentech covers the core electrical systems of the entire vehicle:

- New Energy Vehicle Three-Electric Systems: Connects power batteries, BMS (Battery Management System), and motor controllers to ensure stable transmission of high voltage and large current.

- Energy Storage and Charging Facilities: Adapts to energy storage devices and fast-charging infrastructure, supporting efficient energy interaction in high-power charging scenarios.

- Intelligent Driving Modules: Provides low-loss signal channels for ADAS sensors and domain controllers, supporting the implementation of autonomous driving functions.

Leveraging its full-industry-chain layout, Denentech realizes one-stop services from mold development to automated assembly, balancing product consistency and customized response speed, and helping automakers optimize wiring harness layout and reduce vehicle weight.

- High-Voltage Upgrade: Focuses on 800V+ platforms, enhances thermal management and insulation performance, and adapts to the upgrade of fast-charging technology.

- Integrated Innovation: Integrates high-voltage interlock (HVIL) and signal transmission functions, reducing the number of components and improving system reliability.

- Customized Services: Relies on mold and automation capabilities to provide differentiated specification customization, covering special application scenarios.

- Flexible Customization: Supports pin length customization on demand to meet different installation spaces and connection requirements.

- Diverse Plating Options: Offers multiple plating solutions such as tin plating and gold plating, adapting to different conductive performance and corrosion resistance requirements.

- Professional Technical Docking: The R&D team provides full-cycle support including selection consultation and scheme optimization, efficiently solving application problems.

Adhering to the philosophy of "Teamwork, Integrity, Innovation, and Gratitude", Denentech empowers the vehicle connectivity field with nearly 20 years of precision manufacturing experience. In the future, it will continue to iterate technologies and provide higher-quality connectivity solutions for the electrification and intelligent development of the automotive industry.