The spring pogo pin structure usually consists of pluger, spring and barrel. The surface coating is generally gold-plated, which can better enhance its anti-corrosion function, mechanical performance, electrical performance, etc. This pogo pin connector is mainly used for current transmission and signal connection in electronic devices, and has technical characteristics of reducing the weight of the equipment and shrinking the appearance size.

Built-in spring probes can flexibly make contact, eliminating assembly deviations and vibrations, ensuring stable connection.

The miniaturization design is compatible with high-density integration. The gold plating process achieves low resistance, wear resistance and corrosion resistance.

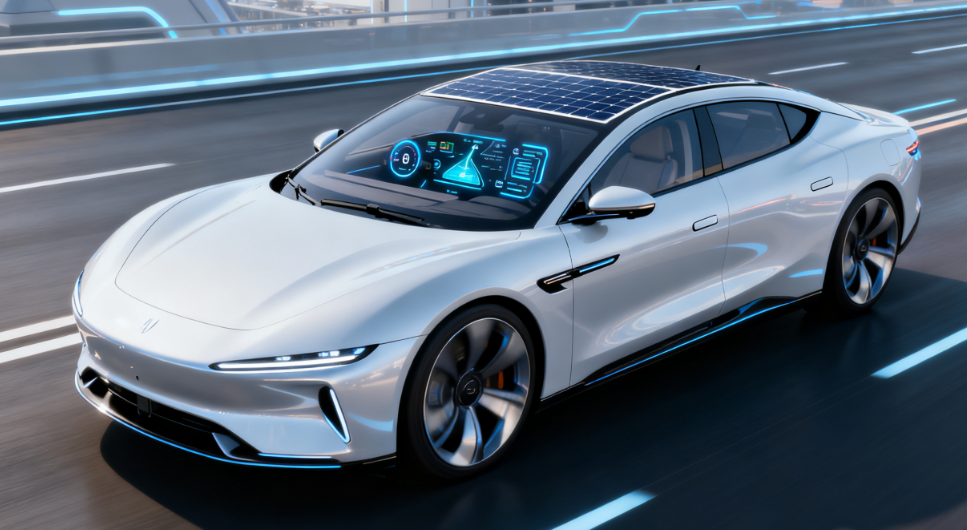

Covering the fields of consumer electronics, automotive electronics, medical equipment and aerospace.

In base stations, routers and other communication devices, modules connect and transmit signals.

In the vehicle-mounted electronic system, it is responsible for connecting sensors, entertainment systems, etc.

Provide precise signal and power connections for aerospace equipment such as satellites and spacecraft.

Used inside portable medical devices to achieve signal and power transmission connections.

Denentech offers a comprehensive range of Pogo Pin connector products, providing a complete solution from standard purchase to customization.

Contact us NowRich in specifications, highly adaptable, facilitating high-density integration, and supporting flexible customization.

The pogo pin male socket is a precision connector that mates with the female socket to conduct circuits. It features spring for vibration deviation compensation, gold plating for low resistance and wear resistance, and compact size for high-density integration. It supports mounting methods like SMT and DIP, with pitch specifications such as 1.27mm and 2.54mm, allowing flexible selection based on equipment needs. It is widely used in precision electronic devices.

The pogo pin female socket is a precision connector component that mates with the male socket to conduct circuits. It has internal contact structures for the male pin, featuring stable connection, corrosion-resistant and wear-resistant surface, and compact size. It supports multiple mounting methods such as SMT and DIP, offers pitch specifications like 1.27mm and 2.54mm, and can be selected based on equipment space and assembly needs. Widely used in consumer electronics, medical devices, automotive electronics, etc.

Whether you need standard products, customized designs, or bulk purchases, Denentech can offer you professional services.