Magnetic connector usually needs to meet a series of standards in waterproof design to ensure its reliability and durability in wet or liquid environment. The following are some common waterproof standards and related points of magnetic connector:

1.IP hierarchy

IP67 grade: Magnetic connectors are usually required to meet at least IP67 grade, which means that they can maintain waterproof performance when completely immersed in water. The number "6" represents the resistance to dust, while the number "7" represents the resistance to water.

2.Sealing material

Silica gel seal: Magnetic connectors usually use high sealing materials such as silica gel to ensure that every part of the connector can be effectively waterproof. These sealing materials can not only resist moisture penetration, but also maintain flexibility in the normal use of connectors.

3.Connector structure

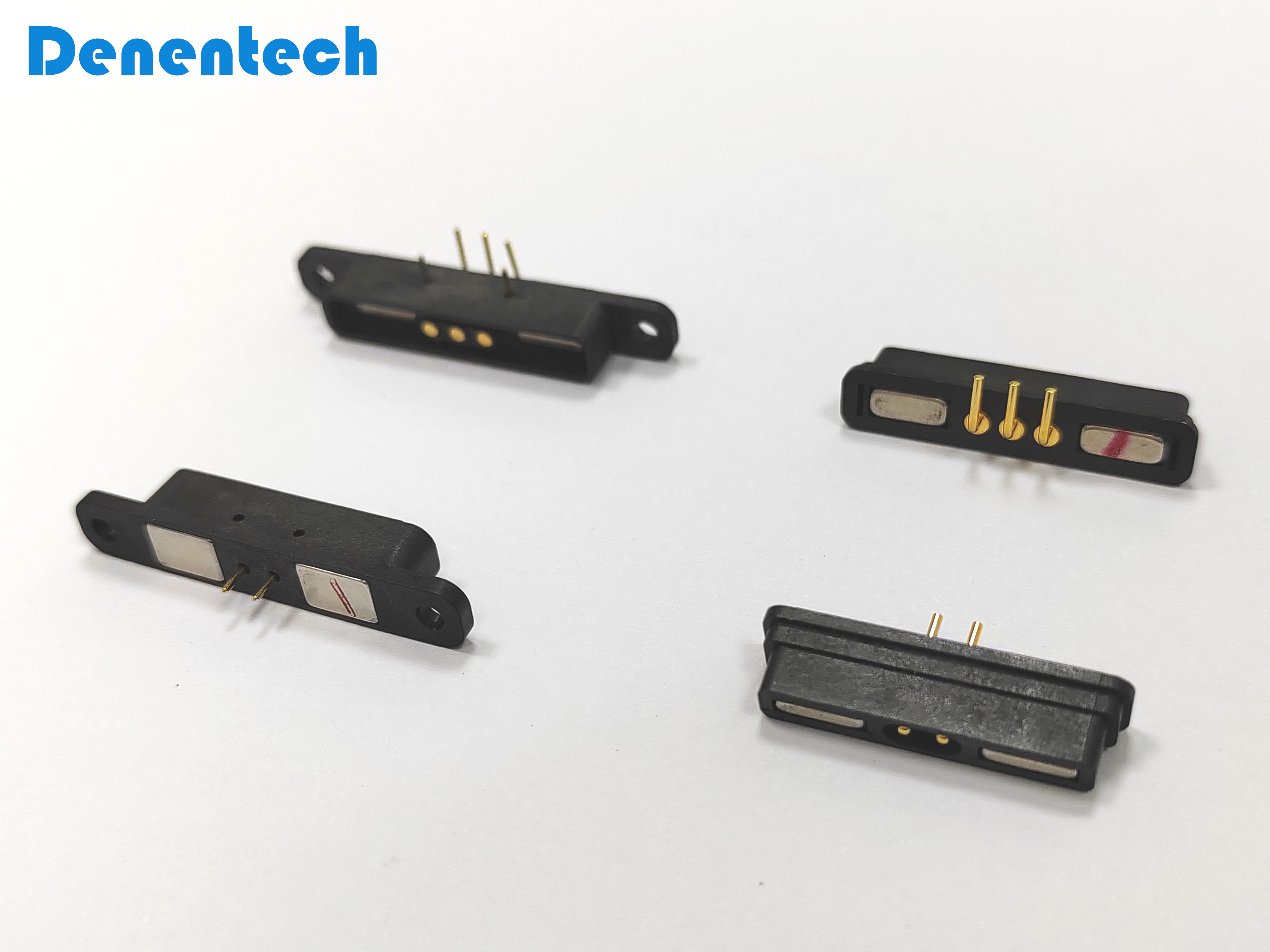

Integral molding design: In order to improve waterproof performance, magnetic connectors often adopt integral molding design to reduce gaps between parts, thus reducing the possibility of moisture entering.

4.Anti-corrosion treatment of magnetic materials

Anti-corrosion coating: The magnetic material on the magnetic connector may be at risk of corrosion, especially in wet environment. Therefore, the magnetic materials of connectors are usually subjected to anti-corrosion treatment to prolong their life and maintain the connection performance.

5. Operating temperature range

Wide working temperature range: in order to adapt to different environmental conditions, magnetic connectors are usually designed to have a wide working temperature range to ensure that they can still maintain waterproof performance under extreme temperature conditions.

6. Maintainability and durability

Easy-to-maintain design: Some magnetic connectors are designed with maintainability in mind, so that users can easily clean or replace waterproof seals and ensure that connectors maintain a high level of waterproof performance for a long time.

Generally speaking, the waterproof standard of magnetic connector is mainly based on IP rating system, and depends on the comprehensive consideration of sealing materials, connector structure, anti-corrosion treatment of magnetic materials and working temperature range. These standards and design features ensure the reliability and stability of magnetic connector in various harsh environments.